Boiler system

Overview:

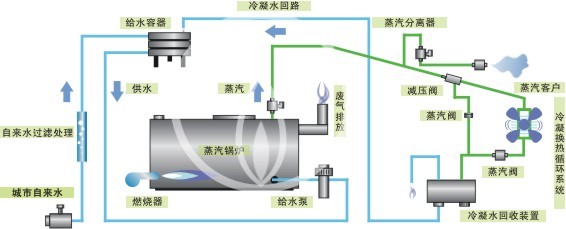

II. Boiler Operation Diagram:

III. Scale Formation:

Boiler water sources include surface water (rivers, lakes, groundwater, deep wells) or municipal tap water. These untreated natural waters are collectively called raw water. They contain various dissolved substances and impurities, with mineral salts and gases existing in molecular or ionic states.

When untreated feed water containing impurities enters the boiler, after continuous operation, evaporation and concentration occur. When the concentration of impurities (dissolved solids) in the boiler water reaches saturation, precipitation occurs, forming a white scale layer on the boiler drum and tube walls.

The boiler’s thermal efficiency and fuel economy depend not only on its design and manufacture but also on water quality and whether proper water treatment is applied.

IV. Harmful Effects of Poor Water Quality on Boilers:

Poor water quality leads to scale formation on heated metal surfaces, causing metal corrosion and deteriorating steam quality, which affects boiler safety, economy, and stable operation. Once scale forms on the boiler’s heated metal surfaces, the harmful effects include:

1.Fuel Waste

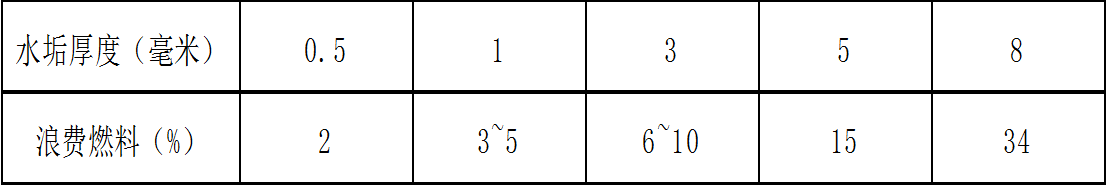

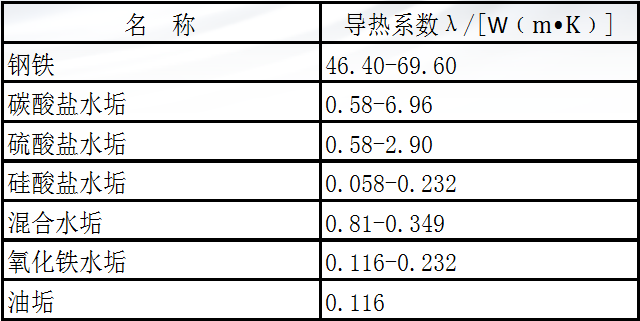

Scale has poor thermal conductivity, with a thermal conductivity coefficient tens or even nearly hundred times lower than metal. Scale formation deteriorates heat transfer, increases flue gas temperature and heat loss, leading to higher coal consumption, reduced boiler efficiency, and fuel waste. According to industry measurements, the relationship between scale thickness and fuel waste is shown in the following table:

2、Heating Surface Damage

Due to poor heat transfer from scaling, achieving rated boiler output requires more fuel consumption. However, limitations in furnace volume, grate area, and flue gas temperature result in reduced boiler output.

4.Metal Corrosion

Excessive free sodium hydroxide or low pH levels in boiler water (standard value 9.0-10.0), along with high neutral salt content, can cause metal corrosion. High levels of corrosion products can lead to under-deposit corrosion in water-cooled wall tubes.

5.Steam Quality Deterioration

Due to impurities in boiler water, as it continuously evaporates and concentrates, salt concentration and surface tension increase, creating foam layers on the boiling surface. When foam bubbles burst, high-salt water droplets are carried away with steam, causing priming and foaming phenomena, which contaminate steam quality. In high-pressure boilers, certain components like silicon selectively dissolve in steam, increasing impurity content and causing salt deposits in superheater tubes and turbines.

6.Increased Maintenance and Operating Costs After scaling occurs in boilers or thermal equipment, safe operation time is reduced. To ensure production safety and prevent accidents, equipment must be shut down for inspection and maintenance. Issues like leaks, cracks, bulging, deformation, and corrosion caused by scale force early maintenance, increasing maintenance costs and overall operating expenses.

7.Impact on Safe Operation

During normal boiler operation, heated metal quickly transfers heat to boiler water, with a temperature difference of 30-100°C. When scale is present, heat transfer is blocked, making it difficult to transfer heat to the water, causing sharp temperature increases and significant reduction in metal strength.

8.Shortened Boiler Lifespan

Scale attached to boiler heating surfaces, especially inside tubes, is difficult to remove. Frequent shutdowns for cleaning increase maintenance costs and consume labor and resources. Regular mechanical and chemical descaling methods can damage heating surfaces, shortening the boiler’s service life.

V. Comprehensive Conclusion

As shown above, poor water quality leads to scaling, causing a series of harmful issues in boiler systems. To ensure safe boiler operation, efficient energy utilization, and prevent scale formation, proper boiler water treatment is essential.